CNC Digital Knife Cutter

Discover Precision Cutting with Our CNC Digital Knife Cutter

About the CNC Knife Cutter

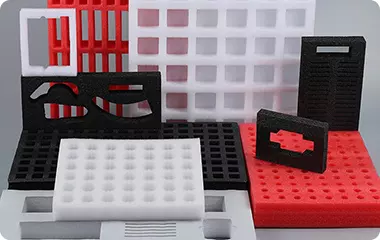

CNC digital knife cutters are used in the precision cutting. These machines excel in swiftly executing a range of processes, including full-cut, half-cut, milling, perforation, and marking. By addressing the challenges associated with cutting special-shaped images, they enhance production efficiency and reduce labor costs.

The CNC digital knife cutters reduce the risk of defects arising from manual tool errors. This ensures users achieve high-quality cuts with greater speed, stability, and accuracy at a lower cost. The result is an improvement in the competitiveness of users in the market, allowing them to capture a larger share. These digital flatbed cutters play an important role in diverse industries such as graphic industry, packaging industry, textile industry, leather industry, gaskets, stickers, foam, foils and composite materials.

Knife cutting, also known as blade cutting, employs various technologies and tools, including fixed knife, oscillating, or round knives, as well as milling heads, enabling its application across a spectrum of materials. This technique is well-suited for intricate cuts on flexible or semi-rigid materials in sheet form. The precision of knife cutting makes it ideal for working with composite materials, foams, rubber, plastic, as well as textiles, leather, glass fabric, cardboard, wood, and many others.

Operating a knife cutting machine is straightforward, similar to a CNC milling machine where knives can be installed. This industrial tool proves to be the most suitable solution when precise and fine cutting is required for various materials. The CNC system enhances the blade’s precision, ensuring burr-free cutting regardless of the material being processed.

Options for CNC Cutting Machine

There is a wide variatie of options for our CNC Digital Knife Cutting Machine. This way we can customize the machine completely to your needs.

Advantages of our knife cutting machine:

Seamless steel, good stability

SinoTech knife cutting machine uses seamless steel welded bed, good stability, not easy to deform.

High precision

Square rail and helical rack transmission, high precision.

Big power vacuum pump

Big power vacuum pump works with the vacuum table, big suction and can fix the material very stable.

Flexible cutting size

Computer graphics, accurate size, flexible cutting size.

Oscillating Knife Tool

Most popular tool in CNC cutting machine, because it can cut series of materials such as leather, carpet, composite materials, cardboard, etc.

Round Knife Tool

Usually for good breathable material, such as fabric, Kevlar, dry carbon fiber fabric, leather, etc. The round knife can also cut some impermeable materials, the cutting speed is relatively fast, but it is not as fine as the oscillating knife because the blade size of the round knife is larger than that of the vibrating knife.

Pneumatic Knife Tool

For cutting thick or hard material such as thick rubber, thin PTFE, EPE, Corrugated paper, honeycomb cardboard, etc.

Drag Knife Head

Application: Soft pvc, PP Synthetic Paper, mobile, car sticker etc. The drag knife will not vibrate when cutting the material, so there will be no vibration lines on the edge of cutting some film materials, and the cutting edge will be smoother

CDD Camera

For cutting printed materials, to find mark points on the board to get the position of design, then cut along the edge.

Japan Panasonic Servo Motor And Drivers

High precision, high speed and good stability. Cooperate with planetary reducer to increase torque and make the machine more powerful.

Honeycomb Aluminium Adsorption Table

Fan-shaped adsorption hole, large adsorption force, not easy to deform after long-term use.

Vacuum Pump

Work with the vacuum working table to fix the material, big power for better suction.

Creasing Tool

Press creasing on the cardboard or PP Hollow sheet for easy folding.

V-Cut Tool

Bevel cutting, angle cutting. Acoustical board, soft pvc, honey/corrugated carton, insulation board another industries.

Half-Cut Tool

For cutting stickers surface layer.

Milling Tool

For cutting hard material, such as acrylic, MDF. And slotting on EVA, EPE foam.

400W Oscillating Knife Tool

Most suitable for cutting EVA foam, it can cut the EVA with a smooth edge, no burr.

Mark Pen

To write numbers and letters on the material.

Red Light Positioning Function

Precise cutting positioning, accurate demonstration of cutting path and range before cutting.

Holland Ammerala Beltech Felt

To protect both working area and blade when machine cutting.

Auto Feeding Working Table

Suitable for roll material, machine will continue to cut after auto feed.

Wide Range of Applications

Our CNC Digital Knife Cutting Machine works for a wide range of industries including car interior, packaging, textile, furniture, composites, gasket and advertising printing.

Composite

Textile

Car Interiors

Leather

Carpets

Foam

Gaskets

Signage & Stickers

Carboard & Carton

What is an Automatic Digital Cutting Machine?

What Is an Automatic Digital Cutting Machine (CNC Knife Cutter)? An automatic digital cutting machine, also known as a CNC knife cutter, is an automated precision cutting system equipped with a CNC (Computer Numerical Controlled) controller. It excels in high-precision cuts of heavier flexible and semi-rigid materials. The machine operates with multi-tool blades, including oscillating knife, oblique knife, circular knife, punching knife, milling knife, punch roller, or marking pen. For enhanced precision, optional features like CCD camera and projector are available.

Frame

Can be made in almost every size! The strong frame ensures a stable machine and forms the base for a stable platform which will ensure precise cutting.

Precision linear rails/guidance

All axes have linear rails to ensure accurate and repeatable movements. That's how we can ensure a much higher precision rate.

Operator Console

Ergonomic operators console with build in touch screen. Easy connection can be made with UTP cable between machine and laptop or PC. Full system in English.

Frequently Asked Question

Tell us the materials you want to cut and the thickness of your materials. Then we will provide you with the best solution possible.

The consumption parts for the machine are mainly the blades. Maybe after long time use you can replace the felt bed, but when used correctly this will have a long lifetime.

The machine will be wraped with film and foam and transported in a Free-fumigation wooden box. This box is specialy made for long time transport. The machine will usually be sent by sea or by train/truck. Thirdly, we will arrange insurance for the machine during transportation.

We will always support you with all of your questions.

The common standard models will be produced in 10-15 working days. Customized models will be around 25-30 working days. Transport time will be depending to the actual location, we will arrange this for you.

We are already making these cutting machines since 2008.

We will help you to be prepared before the machine arrives at your facility.

Yes! We have demo machine at our facility. You can also send us the material you want to cut. Then we can make a video for you or you can visit us to see everything live.

Yes, of course. We can bring you in contact with them.

Transform Your Production with Custom CNC Cutting Solutions

At SinoTech, we’re committed to providing tailored solutions that meet your unique cutting needs. Request a personalized quote today to unleash the power of precision cutting in your production process. Our team is ready to assist you in finding the perfect CNC digital knife cutting solution for your business.